Basic Approach

The Maruha Nichiro Group, which uses marine resources as its main source of business activities, recognizes that resource depletion is inextricably linked to its business survival, and poses a risk with great impact that could lead to the decline or end of its business. We will continue to pursue technologies and systems for the effective use of resources.

Results of the Previous Medium-Term Management Plan (FY2022–2024)

Materiality: Contributing to a recycling-oriented society

KGI (the figure which wants to have 2030): We have built a workplace environment where diversity is respected, and employees feel safe and comfortable to work

Responsibility Department: Plastics Use Reduction Project,Maruha Nichiro Sustainability Department (former Corporate Planning Department sustainability group), Logistics Department

| KPI | Target | Self-evaluation and problem of the prometaphase management plan | ||

|---|---|---|---|---|

| The aim year | Target value | Progress result comment | Self-evaluation | |

| Reduction rate of plastic usage (including switching to bioplastic, recycled materials, etc.) (MN*) | 2030 | 30% or more | Reduced plastic consumption by 7.0% compared to FY2020 | ★★☆☆☆ |

| Food loss (product waste) reduction rate (Domestic G) | 2030 | 50% or more | Reduced food loss by 64.9% compared to FY2020 | ★★★★★ |

| Recycling rate of food waste (Domestic G) | 2024 | 99% or more | Recycling rate of food waste, etc. 98.9% | ★★★☆☆ |

| Extended shelf life of commercial products assessed as extendable (MN) | 2030 | 100% | Testing is ongoing to extend the shelf life of some products | ★★★☆☆ |

★★★★★ : KPI for FY2030 achieved.

★★★★☆ : Progress toward achieving KPI for FY2030 in advance.

★★★☆☆ : KPI for FY2024 achieved or progress toward achieving KPI for FY2030 as planned.

★★☆☆☆ : KPI delayed.

Medium-Term Management Plan (FY2025–2027) KGI, KPI

Materiality: Contributing to a recycling-oriented society

KGI (the figure which wants to have 2030): We have built a workplace environment where diversity is respected, and employees feel safe and comfortable to work

Responsibility Department: Plastics Use Reduction Project, Maruha Nichiro Sustainability Department (former Corporate Planning Department sustainability group), Logistics Department

| KPI | Target | |

|---|---|---|

| 2027 | 2030 | |

| Reduction rate of plastic consumption (compared to FY2020) Including switching to biomass, recycled materials, etc. (Maruha Nichiro Co., Ltd.) | More than 20% | More than 30% |

| Setting targets for reducing plastic consumption at production plants (Domestic Group) | Goal setting (2025) | ー |

| Food Loss (Product Waste) Reduction Rate (Compared to FY2020) (Domestic Group) | More than 70% | More than 80% |

| Recycling rate of food waste, etc. (Domestic Group) | 99% | ー |

| Extension of the shelf life of commercial products that were evaluated as extendable (Maruha Nichiro Co., Ltd.) | 100% | ー |

| Analysis and evaluation of water resource risks and opportunities, countermeasures, and consideration of countermeasures | Analysis of risks, opportunities, and countermeasures | ー |

Main Initiatives in FY2024

“Deplastification”: Reducing the Amount of Plastics Used for Containers and Packaging

Promotion Framework

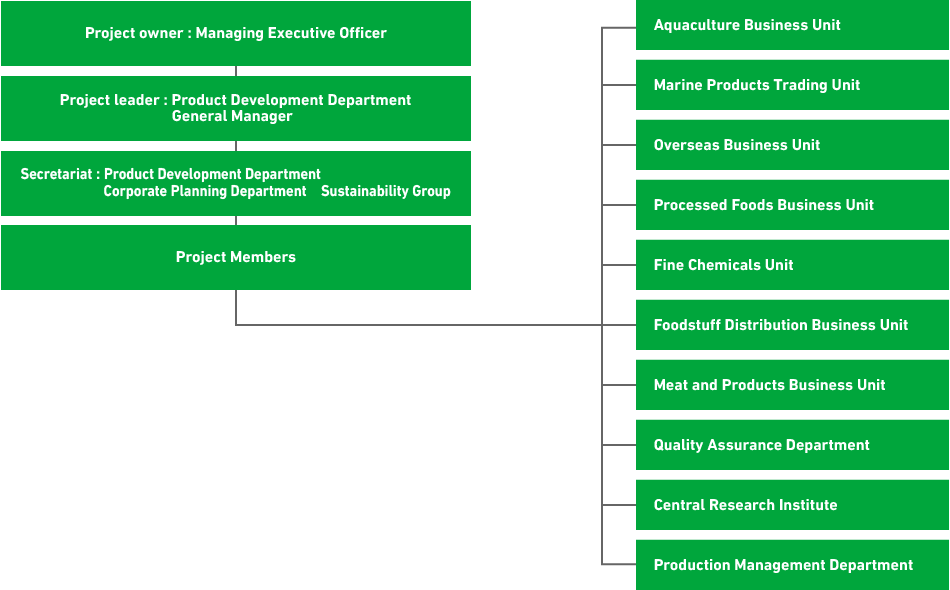

Since it is necessary for the entire Company to share information and cooperate on the materiality, which involves a large number of units, from FY2022 we launched a project to reduce the amount of plastics used. With the Managing Executive Officer as project owner and the General Manager of the Product Development Department as project leader, we have established targets for FY2030 and are proceeding with specific efforts to achieve the targets.

Plastics Use Reduction Project Promotion Structure

Establishing Targets for Reducing the Amount of Plastics Used for Containers and Packaging, and Status of Progress

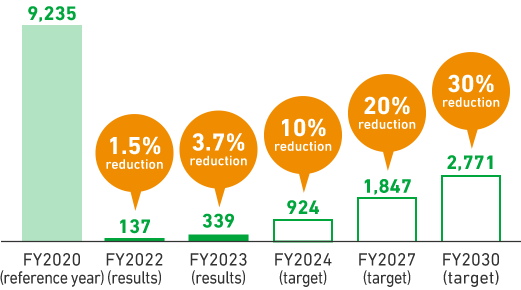

The reduction in plastic use in containers and packaging is set at FY2020, with a KPI of 30% reduction by FY2030. In FY2024, we were able to reduce 306 tons, and the cumulative reduction from FY2022 is 644 tons (approximately 7.0%). Initiatives are gradually spreading among employees, and we will continue to promote further reduction measures.

Reduction in Petroleum-Derived Plastics

Efforts to Save Resources on Product Containers and Packaging

The Maruha Nichiro Group is working to develop containers with low environmental impact. By reducing the weight of containers, it is expected to not only save resources but also reduce CO₂ emissions during distribution due to the reduced weight.

In FY2022, Maruha Nichiro reviewed the composition of the films used in its commercial frozen food products, rice and cup gratin, and reduced their size while maintaining sufficient strength, resulting in a 16.7-ton reduction in plastic use.

In FY2023, the company further expanded the range of products covered by the program and started reducing the amount of plastic used for trays in addition to film, resulting in an annual reduction of 75 tons of plastic usage.

Food Loss Reduction Initiatives

To reduce food loss* throughout the Group, we launched the Food Loss Reduction Project in FY 2022. As a result of various measures implemented under this project, efforts were expanded to the entire group, and progress was made beyond the initial plan, achieving the reduction target for FY2024 ahead of schedule in FY2023 and The project was dissolved.

From FY 2024, the Sustainability Department and Logistics Department of Maruha Nichiro Corporation will take the lead in promoting further activities to achieve the fiscal 2030 reduction target under the supervision of the Sustainability Promotion Committee

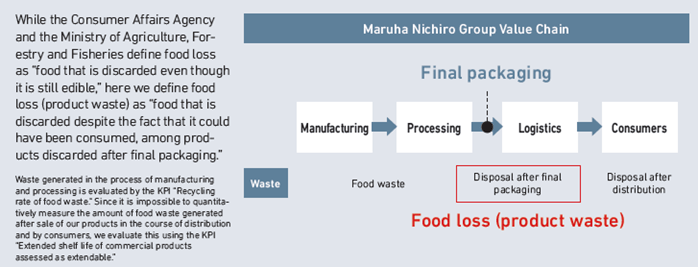

What is Food Loss?

Setting Food Loss Reduction Targets and Status of Progress

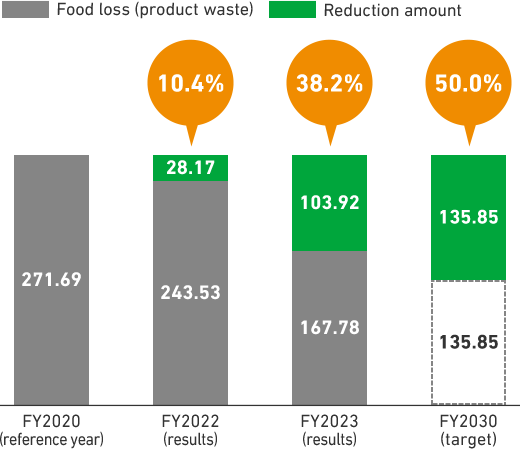

In fiscal 2020, food loss at Maruha Nichiro's business units and domestic group companies was 271.69 tons. In order to achieve the KPI "Reduce food loss by 50% by 2030 compared to FY2020 in the Domestic Group" during the previous medium-term management period, we implemented various measures such as changing the awareness of all employees and establishing and operating a regular donation scheme for frozen foods that generate the highest amount, resulting in a reduction in food loss in FY2024 by 64.9% (approximately 175 tons) compared to FY2020. We were able to achieve our FY2030 target ahead of schedule. In response to this result, we have revised our FY2030 target upward to reduce food loss by 80% compared to FY2020. We will continue to work with each business division and group companies to promote various measures to achieve our FY2030 targets.

Reduction of Food Loss

Surveying the Current State and Discussing Response Measures

At Maruha Nichiro Group, most food loss is generated by business divisions belonging to the Processed Foods Business Unit and Foodstuff Distribution Business Unit and by Group companies, and a large amount of food loss tends to be generated by frozen foods compared to non-frozen foods. The main reasons for this are that frozen foods, which are also often produced outside of Japan, are prone to packaging damage when shipped in transport containers, and a certain amount of waste is also generated by products left over from box-opening sampling inspections at the time of import.

Responding to Food Loss from Exterior Packaging Damage

To address food loss caused by exterior damage, we will continue to promote reexamination of packaging forms, reduction of matching and banding, modularization of carton cases, and pallet transportation.In FY2023, we established standards for exterior damage of frozen foods for commercial use in cooperation with logistics companies, and as a result, we were able to significantly reduce food loss of frozen foods for commercial use.By continuing to operate this standard in fiscal 2024, we were able to significantly reduce food loss throughout the year.

Example of Damaged Exterior Packaging

Establishing a Donation Scheme for Frozen Foods

We have been donating food to food banks since 2009. However, due to the shipment costs and lack of sufficient frozen storage facilities at food banks, we had not made progress on the donation of frozen foods, which make up a large portion of our food loss. As we considered how to overcome this problem, we formed a partnership between Food Bank Kanagawa and logistics companies that store our products . This enabled us to establish a scheme by which Food Bank Kanagawa receives our frozen products directly from the warehouse in periodic donations. As a result, donations of frozen products in addition to non-frozen products have increased dramatically, bringing the total amount of FY2022 donations to 16.87 tons.

In FY 2023, the target products were expanded to include commercial use, and donations of products with damaged packaging were also made in coordination with Food Bank Kanagawa.

In FY2024, we also started donating food loss generated by group companies that use the same logistics company, bringing the total donation volume to approximately 43 tons. The Group will continue to make regular donations of frozen foods.

Regular Donation Scheme Flow

Maruha Nichiro Receives the Commissioner of the Consumer Affairs Agency Award at the FY2023 Food Loss Reduction Promotion Awards

Maruha Nichiro received the Commissioner of the Consumer Affairs Agency Award at the FY2023 Food Loss Reduction Promotion Awards presented by the Consumer Affairs Agency and the Ministry of the Environment. The award was presented to Maruha Nichiro in recognition of the ripple effect on other companies and future potential resulting from its efforts as a major industry player to establish a sustainable frozen foods donation scheme through a three-way collaboration between a food manufacturer, a logistics company, and a food bank, as well as the progressive nature of frozen foods donation.

* The “Food Loss Reduction Promotion Award” is given to those who have made efforts to promote food loss reduction that are widely disseminated to consumers, etc., and that are expected to be effective in reducing food loss and to have a ripple effect.

Food Loss Generated by Distribution or Consumers After Sale

In addition to extending the shelf-life of non-frozen foods, which we have been implementing thus far, in 2022 we began selling some frozen foods for commercial or institutional use with shelf-life extended by six months—extended from 12 months to 18 months—by checking the quality through storage testing.

We are making steady progress on reducing food loss through the implementation of various measures and we will continue our efforts to drastically reduce food loss in order to achieve our reduction target for FY 2030.

Water Resources Risks and Opportunities

Basic Approach

In recent years, natural disasters such as droughts and floods have occurred frequently due to climate change and other factors. In addition, as the world's population grows, the risk of water shortages is increasing in regions. The Group's business also relies on water resources, especially at processed food factories, and at the same time affects water resources. Under these circumstances, in the new medium-term management plan starting in fiscal 2025, we have set water resource risk assessment as a KPI for the materiality "Contribution to the Realization of a Recycling-Oriented Society." After analyzing and assessing the risks of the Group's water resources, we will identify priority areas with high risks and consider countermeasures.

Results of Water Resource Risk Survey

In 2025, the Maruha Nichiro Group evaluated water resource risks, drought risks, water quality risks, flood risks, etc. at 101 domestic and 20 overseas sites using tools such as Aqueduct and Water risk filter, and conducted a questionnaire survey for each site to revise the results. The evaluation method evaluated the likelihood and impact of each risk on two axes of five levels (1~5). In addition, in Japan, the risk of flooding due to typhoons and linear precipitation zones is increasing, so we used hazard maps and other means to assess the depth of inundation and identify priority locations where efforts should be taken. From this survey, we have compiled water intake and discharge at major overseas bases and water intake in water-stressed areas. As a result of the survey, water withdrawal from water-stressed areas was less than 1% of the total water withdrawal of the entire group.

Identification of Water Risk Priority Sites

| Water resource risk | Drought risk | Intake water quality risk | Wastewater quality risk | ||

|---|---|---|---|---|---|

| whole | 1 | 1 | 9 | 6 | |

| Japan | 4 | ||||

| Asia (excluding Japan) | 8 | ||||

| Europe | 1 | 1 | |||

| North, Central and South America | 1 | 1 | 1 | ||

Water Intake at Sites Located in Water-Stressed Areas

| In 2020 | In 2021 | In 2022 | In 2023 | In 2024 |

|---|---|---|---|---|

| 36 | 34 | 41 | 39 | 33 |

Identifying Flood Risk Priority Locations

| Number of locations | The water was deep |

|---|---|

| 1 | 3.0~5.0m |

| 9 | 0.5~3.0m |

*Evaluate the flood depth with a high probability scale of 1/30

Annual Water Consumption/Wastewater Consumption (Domestic Production Bases and Major Overseas Production Sites)

Annual Water Consumption/Wastewater Trends

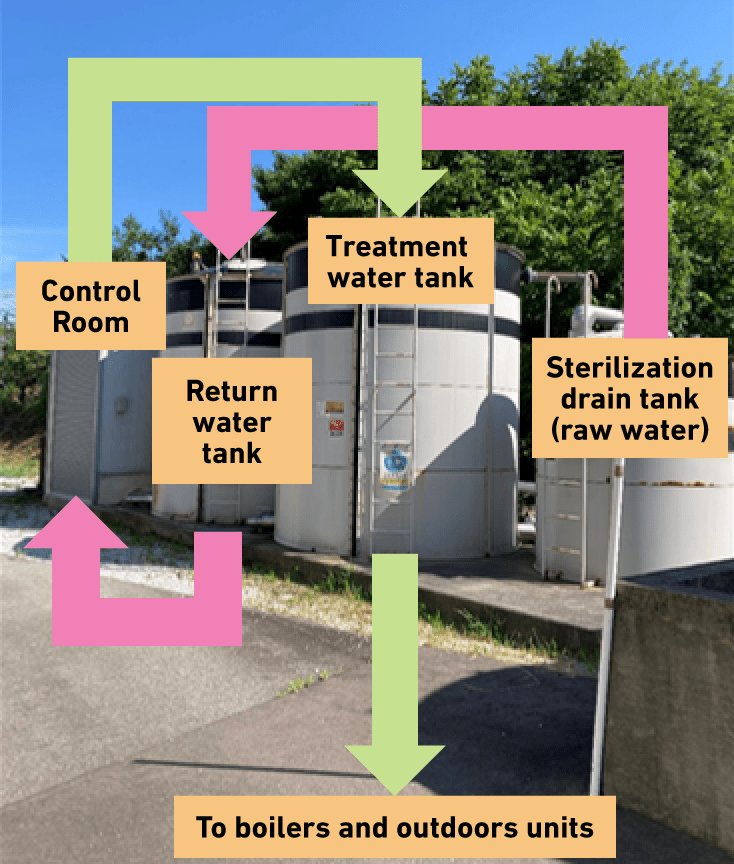

Examples of Water Reuse

In order to promote the circulation of water use, some of the Group's production sites are reusing water by utilizing process wastewater collection and recycling technology to reduce dependence on water intake and improve water intake efficiency in production activities. Maruha Nichiro Yamagata Co., Ltd. treats wastewater from the sterilization process of manufacturing with UF membrane and uses it for water supply to boilers, and sprays it on outdoor units such as air conditioners and refrigerators in the summer to reduce clean water. In addition, the temperature of the treated water is 35~45°C throughout the year, which also leads to a reduction in heavy oil.